It's easy to pour and build a backyard patio made of concrete in this How To article. On a small scale, concrete is fairly easy to work with, but installing an entire patio can be a challenge. It is possible to build an attractive concrete patio yourself, but careful planning and preparation is necessary. Be sure to lay all the concrete at once; a big patio can be broken down into smaller manageable sections using 2x4's.

Once concrete is in place, you're stuck with it forever; replacement is costly and difficult. Planning is essential for a perfect DIY conrete patio.

Build and install forms, making sure they're level and properly graded for drainage. To prevent rain puddles from forming, design a 2% slope (every 10' long will drop 2.5").

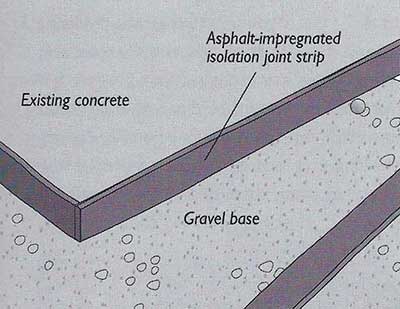

Place and level a 4"-6" bed of gravel; you need a gravel base in areas of poor drainage or freezing temperatures. Be sure to compact the gravel base and rent a compacting machine if necessary.

Check gravel thickness with a homemade template that extends down from the tops of the forms 4" of the finished patio; when it just touches the top of the gravel, the base is thick enough.

A taller slab will be stronger- we recommend 4" thick. Let the gravel extend under the edges of the forms.

If the patio will abut an existing concrete patio or slab, install isolation-joint strips. Attach the strips flush with the top of an existing slab using hardened concrete nails or construction adhesive.

Need Help? Contact a siding contractor in Boise for installation help on exterior services like roof, windows or house siding.

How To Pour a Concrete Slab

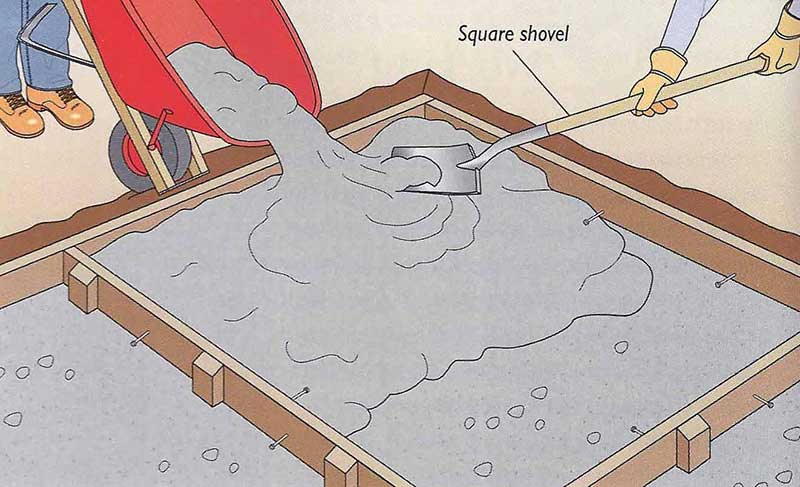

Thoroughly dampen the gravel. Start laying the concrete at one corner of the form while a helper uses a shovel or hoe to spread it (above).

Pour the concrete up against the form and compact it into all corners with a square shovel or mortar hoe; with a hoe, push- don't drag the concrete. But don't overwork the concrete, and don't spread it too far; overworking will force the heavy aggregate to the bottom of the slab and will bring up small particles that can cause defects in the finished DIY concrete patio. Instead, space out your placement along the form, placing each batch against the previous batch to fill the form.

If you plan to leave the dividers in place, finish, and cure the concrete in alternating sections. (Imagine it like a checkerboard and do all the red squares first.) Once they've cured for at least three days, remove the stakes from inside of the remaining sections (black squares) and complete them.

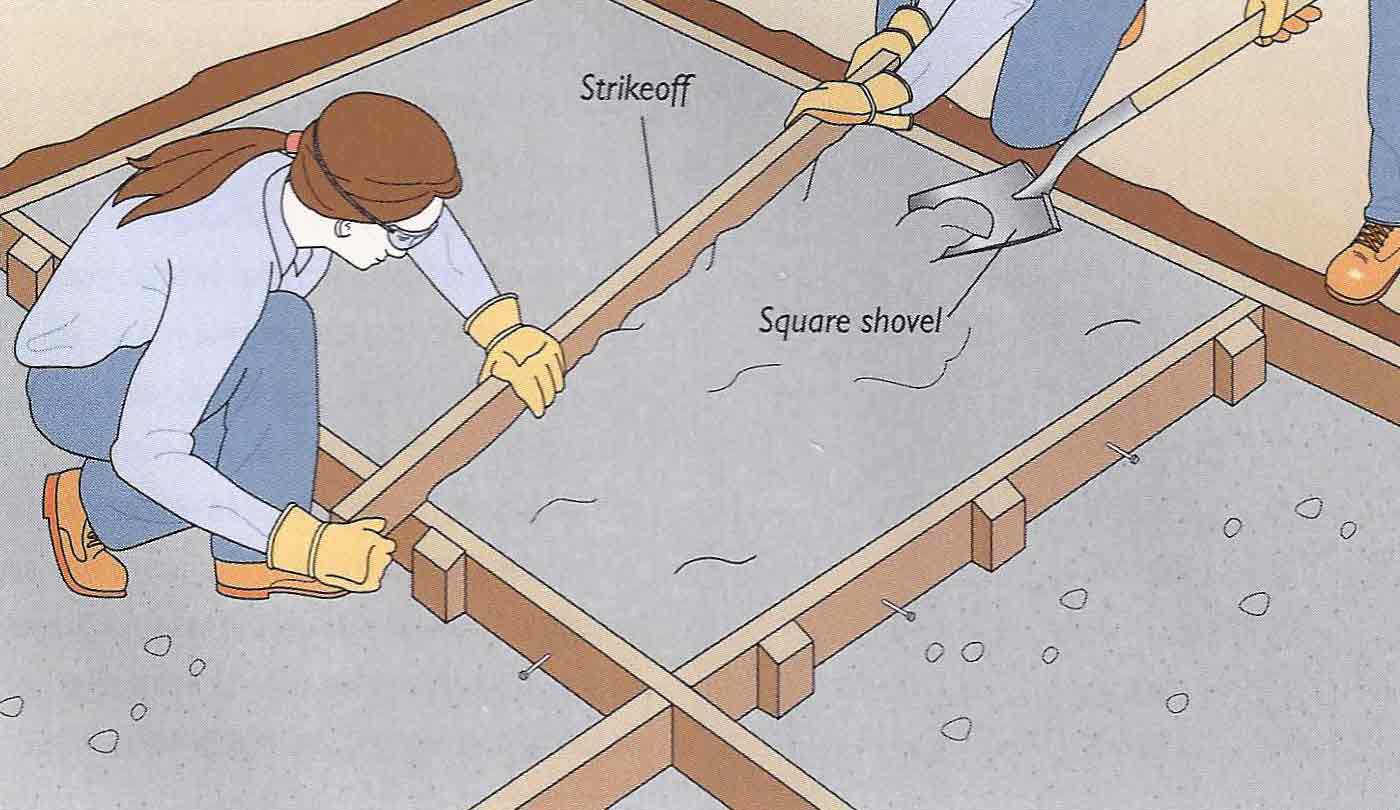

Striking the DIY concrete patio

Move a strikeoff (example above- a straight wood 2x4) across the form to level the concrete. On large jobs, do this batch-by-batch, rather than after all the cement is placed. Move the board slowly along the form, using a side-to-side, sawing motion; be sure to make two passes. Even on narrow forms, two people will make the work faster and more efficient. If necessary, a third person can shovel extra concrete into any corners to save time.

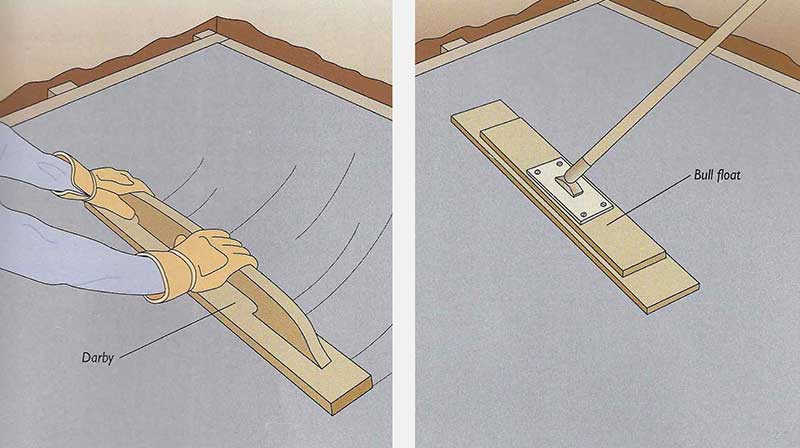

Smoothing concrete patio surface

If you're working on a very small walkway leading to your patio, you can skip this step.) After striking off, use a darby or bull float-depending on the size of your project-for the initial finishing, to smooth down high spots and fill small hollows left after striking off.

Use the darby (above, left) on small DIY concrete projects. Move it in overlapping arcs, then repeat with overlapping straight, side-to-side strokes. Keep the tool flat, don't let it dig in. For larger jobs, use a bull float (above, right). Push it away from you with its leading edge raised slightly. Pull it back nearly flat; overlap your passes.

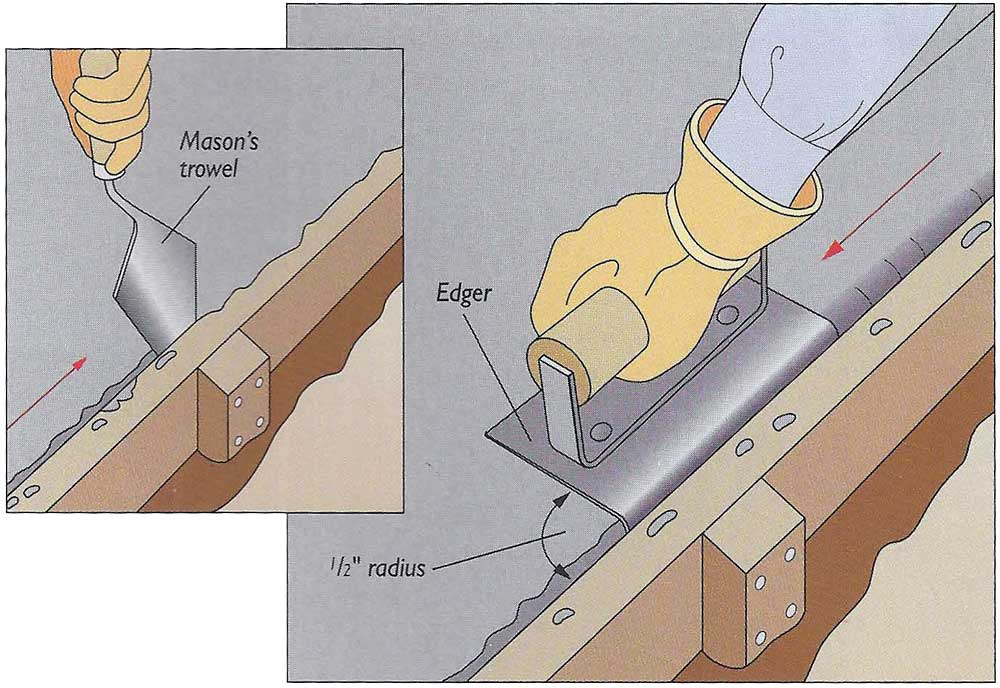

Edging concrete

Giving your Do It Yourself concrete slab or sidewalk a curved edge will help it resist chipping and prevent stub-toes or tripping accidents. To edge the cement, begin by running a mason's trowel between the concrete and the outer edges of the slab form (above-inset). Follow with an edger (above-right) . Run it back and forth to smooth and compact the concrete. Unless the tool has a toboggan end, raise the leading edge slightly as you move it.

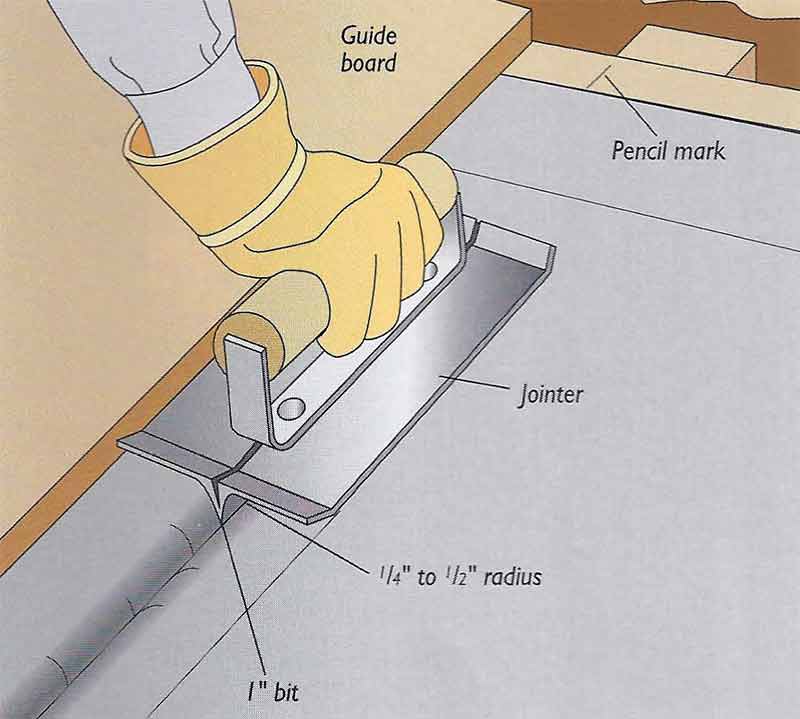

Jointing concrete for controlled cracks

Large slabs of concrete will crack. To control patio cracks you need to set joints with a 1" deep jointer with a straight guide board to make control joints (above). Kneel on a board to reach the middle of a wide slab. Depth of control joints should be one-quarter of the slab's thickness. Control joints can be made at intervals of about 1.5 times the width of the slab but the distance between them should not exceed 30 times the thickness of the patio- 10' for a 4" thick slab.

For concrete made with 3/4" coarse aggregate, reduce the maximum control joint spacing to 8' for a 4" slab. Jointed sections should never be more than 1.5 times as long as they are wide. BONUS TIP: It is better to have more joints, rather than less to prevent cracking.

Measure along the forms to locate the joint and mark them with a pencil. Any edging or jointing marks can be removed by floating- which is next!

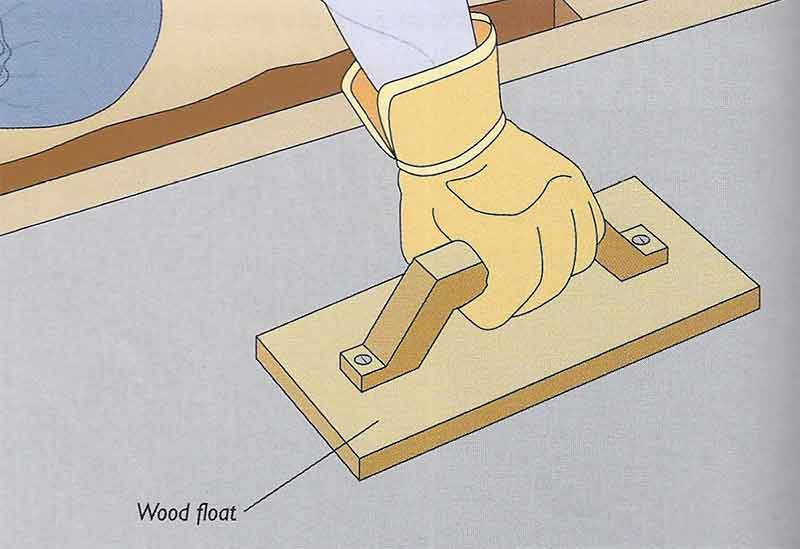

Floating and troweling concrete

Floating and troweling concrete

Now comes the fun part of working with ready mix cement, (well, we think floating concrete is fun.) After the water sheen has disappeared from the concrete, but before the surface has become really stiff, float with a wood float or a magnesium hand float. The latter gives a smoother surface.

With air-entrained concrete, (what we deliver) use a magnesium float- a wood float can tear the patio surface. With both types of float, hold the tool flat on the surface. Once again, to reach the middle of a large slab, kneel on boards and then finish over the board marks as you work backwards.

CAUTION: Don't use a steel trowel on outdoor surfaces, unless you are going to broom-finish afterwards; it creates a very slick surface that can be dangerous when wet. So positively do not use a steel trowel on a patio next to a pool.

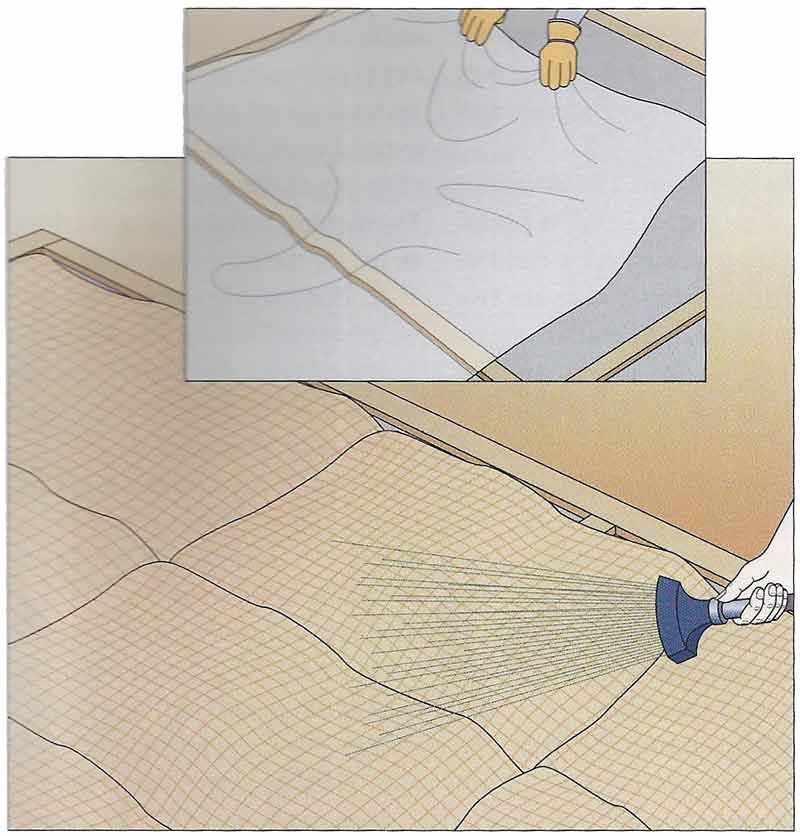

Drying Concrete: curing the DIY patio

Patio slabs need to be moist cured to keep their surfaces from drying too quickly- especially in our high desert heat of Twin Falls, ID. If the surface dries too soon, it will be weak and may later become powdery or crumble away. Cure your concrete by keeping it wet. Cover the slab with burlap, sand, straw, or other material and wet it (above). Wet it down as needed until curing is finished.

Another option is to use plastic sheeting (inset above) or a commercial curing compound. Water evaporating from the slab will be trapped, eliminating the need for wetting.

Whatever method you choose, curing should last a minimum of three days-longer in cold weather- but it's best to let the slab cure for a week, just to be on the safe side. Don't walk on it for at least 3-4 days, nor drive a vehicle until 10 days have passed.

Now it's time to enjoy your new DIY cement patio!

Need More Help? Check back to our site as we will be adding the best "how-to's" on concrete, and articles for do it your-selfers.